With the new high-performance penetration edge, the NX-NVDS and NB-NVDS achieve a level of performance that facilitates peak productivity and process reliability in 7 dimensions!

This FRAISA innovation gives NVDS tools a ground-breaking performance range!

The development of the new penetration edge allows FRAISA to introduce the termhigh-performance penetration. The new high-performance penetration edge cuts easily and clears the chips without disrupting the process.

The cutting data software ToolExpert HelixRamp was developed for the new high-performance tools.

The software can conveniently be started using the FRAISA website. With just a few clicks, you can defi ne the material, tool and penetration strategy, and receive the parameters to be programmed for your machine control or CAM system.

Use the online cutting data calculator ToolExpert HelixRamp without having to download any software!

Use ToolExpert HelixRamp

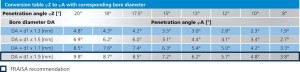

For the cycle programming on the machine, note which entries are relevant for the corresponding control system. For the cutting data, you can fi nd the basic data with φZ and vfZ. You can then use the conversion table below to fi nd φA. It is even faster and simpler with the cutting data software ToolExpert HelixRamp, which allows all penetration parameters to be calculated and compared with just a few clicks!

Program the penetration angle φZ or φA correctly!

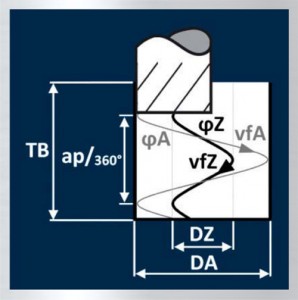

Penetration using helical interpolation is today used as standard to get into pockets, deeper levels or bores. The reason for this is the improved chip removal and the lower process temperatures during helical interpolation. This allows higher penetration depths to be achieved during helical machining. Depending on the machine control system or CAM system used, different input parameters may be required for the same procedure. Typically these are:

- The external diameter of the helical drilling DA

- The central penetration angle φZ

- The speed n and the feed rate vfZ at the center

- The penetration depth TB

FRAISA recommends entering the DA as 1.9xd1 if possible. e.g.: milling cutter diameter d1 = 10 mm, DA = 19 mm

ATTENTION: For cycle programming, it may be necessary to enter other penetration parameters, depending on the machine control system. On some machine control systems (e.g. Heidenhain), it is not the central penetration angle φZ that is needed, but the penetration angle at the outer track φA!

This is entered at the machine (tool table) under “Angle“. The penetration angles at the center φZ and at the outer track φA vary signifi cantly, depending on the DA for the milling cutter diameter. The outer angle φA is always smaller than the central angle φZ.

With other control systems again, the infeed per helical rotation (ap/360°), the radius of the tool tip path (e.g. Siemens) or the radius of the bore (e.g. Fanuc) is required.

In some cases the ramps have to be selected on the basis of the component, e.g. an elongated hole slot. The parameters for programming a ramp are identical on all control systems.

High-performance milling cutter NVDS

High-performance milling cutter NVDS

High-performance milling cutter NVDS For up to 15 times faster penetration