WhizCut Micro Thread Mills vs. Thread Tap

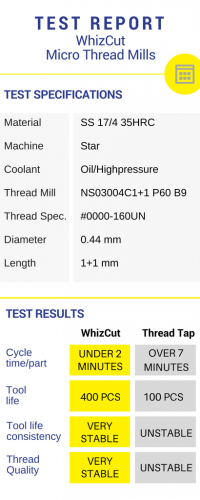

A large American manufacturing company, producing parts for the medical industry, changed from a Thread Tap to WhizCut Micro Thread Mills.

Problem:

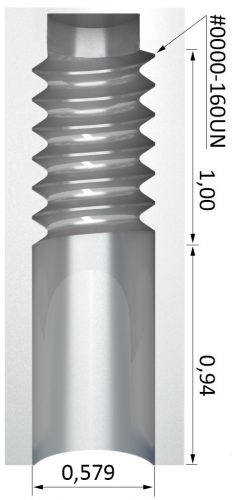

Difficulties producing a #0000 160TPI thread with a consistent quality. The process was time consuming and unstable using a thread tap.

Goal:

Produce the thread more efficiently and stable.

Result:

The cycle time changed from 7.5 minutes to under 2. The process is very consistent and tool life improved from 100 pieces to 400 pieces. Also the thread diameter is completely adjustable.

Download WhizCut Catalogue 2016